A thorough electrical inspection checks the safety, condition, and code status of a home’s electrical system. It helps identify fire hazards and safety risks early. Inspectors examine key electrical components, verify proper grounding, and look for signs of wear or failure.

This approach reflects the most thorough electrical inspections for peace of mind in the USA, where safety standards, code compliance, and clear documentation guide inspection practices.

Key Takeaways

- Thorough electrical inspections review the full home electrical system to identify fire hazards, code violations, and safety risks before they become serious problems.

- Warning signs such as outdated wiring, warm outlets and switches, repeated breaker trips, or missing GFCI protection often indicate underlying electrical issues.

- The inspection process includes visual checks, electrical tests, and code-based review, with different steps for rough, final, and safety inspections.

- Inspection reports clearly explain findings, helping homeowners determine which electrical work is urgent and which can be planned.

- Scheduling an electrical inspection helps ensure safer systems, reduces fire risks, and supports long-term code compliance.

What Makes an Electrical Inspection Thorough

A thorough inspection looks at how the system works as a whole. Inspectors review the electrical panel, branch circuits, circuit breakers, and safety devices. This helps find problems that can overheat or fail under load. A full review supports code compliance and long-term safety.

Thorough inspections also reduce uncertainty. Inspectors replace guesswork with tested results and clear findings. Homeowners gain a better understanding of their home’s electrical system. Peace of mind comes from knowing what is safe and what needs work.

Clear documentation and verified testing are typically handled by licensed electricians in Bergen County. This helps homeowners plan repairs or upgrades with confidence. The most thorough electrical inspections for peace of mind focus on clarity, not assumptions.

Common Electrical Red Flags Found in Homes

What Is the Biggest Red Flag in a Home Inspection

One major red flag is unsafe or outdated wiring. Knob and tube wiring, damaged insulation, or poor splices raise fire risks. These issues often hide behind walls or ceilings. Finding them early helps prevent serious failures.

Outdated Wiring and Overloaded Circuits

Overloaded circuits and poor grounding are also common concerns. Frequent breaker trips, warm outlets and switches, or missing ground-fault circuit interrupter protection can indicate code violations. These problems reduce safety and reliability. Inspections flag these issues so electrical work can be planned.

Many warning signs appear during normal use. Lights may dim when appliances start, or breakers may trip often. Buzzing near the electrical panel or a burning smell can signal overheating electrical components. These signs help inspectors find fire hazards that are easy to miss.

What Happens During an Electrical Inspection

The inspection process follows a clear order. Inspectors start at the electrical panel and check labels, breaker size, and layout. They then review visible wiring, outlets, switches, and junction boxes. This method keeps inspections consistent.

What Needs to Be Done for a Rough Electrical Inspection

A preliminary inspection is conducted before walls are closed. Inspectors check wire routes, box placement, wire size, and proper grounding. This step confirms the installation meets code before it is hidden. Fixing problems early avoids costly changes later.

Electrical Tests Performed During the Inspection Process

Testing is a key part of the inspection process. Inspectors check voltage, polarity, grounding, and GFCI protection. These tests confirm that safety systems respond correctly. Together, testing and visual checks provide a full picture.

A typical inspection process follows a set review path, supported by a documented electrical inspection checklist. Inspectors commonly review:

| Checklist item | What it helps verify |

|---|---|

|

Electrical panel condition and labeling

Main service equipment review

|

Confirms the panel is safe, clearly labeled, and suitable for installed circuits and devices.

|

|

Circuit breakers and load balance

Overcurrent protection review

|

Verifies breakers match circuit demand and reduces overheating risk from overloads.

|

|

Wiring condition and visible connections

Accessible wiring review

|

Identifies damaged insulation, unsafe splices, or visible conditions that raise fire or shock risk.

|

|

Proper grounding and bonding

Fault path and bonding review

|

Confirms a safe fault path and correct bonding, which reduces shock risk and protects devices.

|

|

Ground fault circuit interrupter and GFCI protection testing

Shock protection device testing

|

Confirms GFCI devices trip correctly and provide required shock protection.

|

Electrical Inspection Standards and Manuals

Electrical inspections follow defined standards. Inspectors use the electrical inspection manual and the National Electrical Code as references. These rules set minimum safety and installation requirements. Standards keep inspections consistent and fair.

Local rules may add more requirements. Inspectors review local code updates and enforcement practices. This ensures that results comply with both national and local regulations. Understanding these layers supports accurate code compliance.

Types of Electrical Inspections

What Are the 4 Types of Inspection

There are four main inspection types. These include rough, final, safety, and code-compliance inspections. Each serves a different purpose. Knowing the difference helps with planning.

Rough inspections occur during construction. Final inspections confirm readiness for use. Safety inspections focus on fire hazards and shock risks. Code-compliance inspections often occur during sales or upgrades.

Electrical Inspection Services

Residential Electrical Inspection Services

Electrical inspection services provide formal system reviews by licensed electricians. These include structured electrical home safety inspections. Inspectors document risks and suggest corrections. The goal is to reduce fire risks and improve reliability.

Commercial Electrical Inspection Services

Commercial inspection services address larger and more complex systems. Inspectors review panels, grounding, and life safety systems. These inspections support safe operation in higher-load settings. The same standards apply across property types.

Tools Used During Electrical Inspections

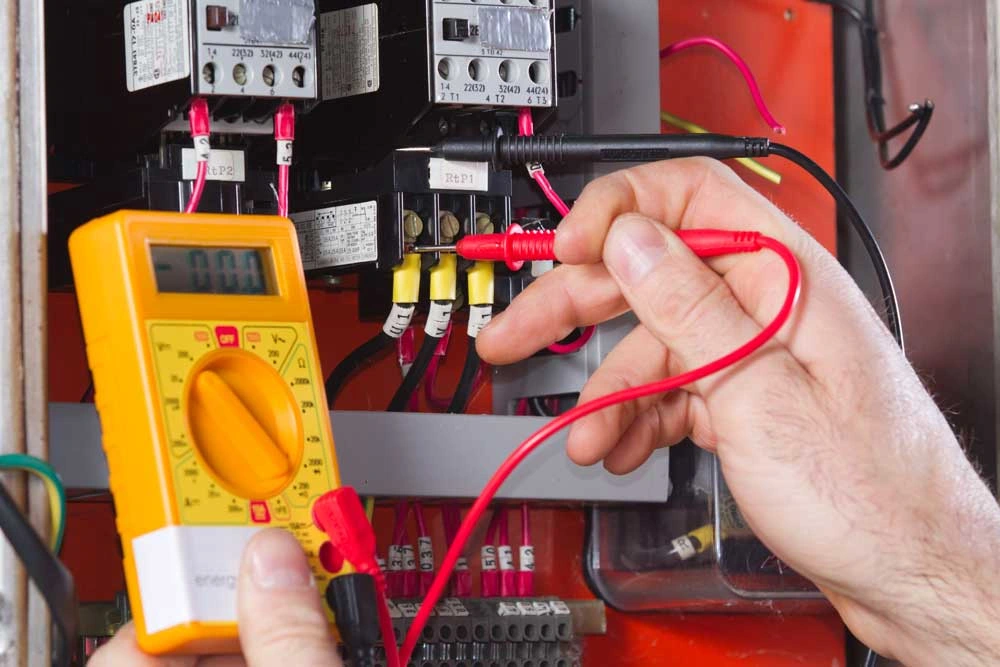

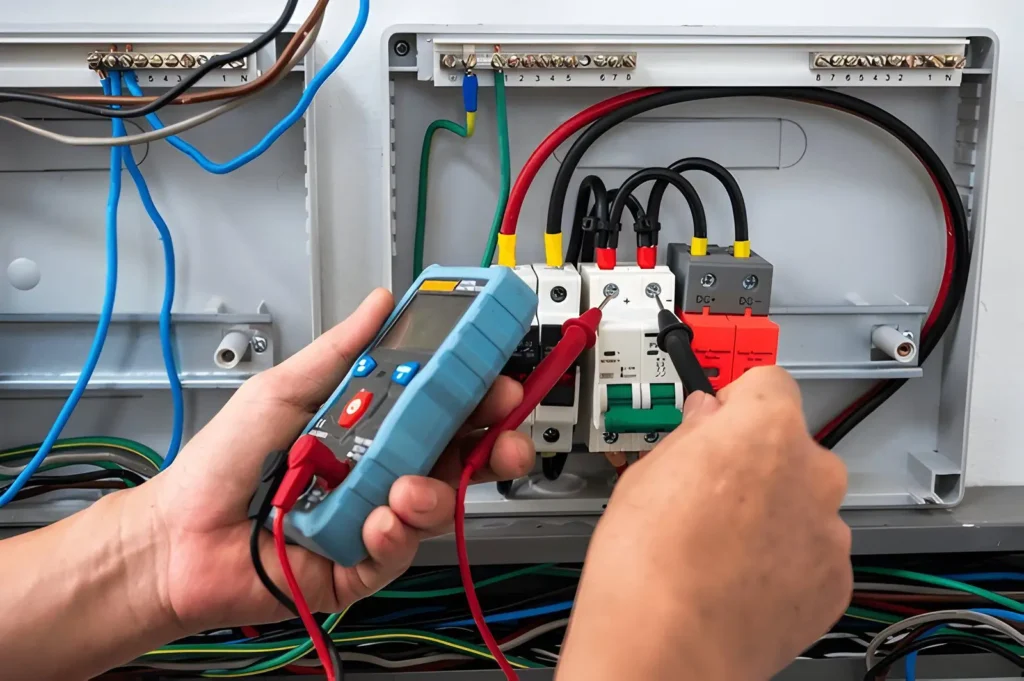

Most Useful Tools for Electricians

Inspectors rely on precise tools. Common tools include multi meters, circuit testers, and insulation testers. These tools measure voltage and continuity. Accurate readings support reliable conclusions.

Testing and Diagnostic Equipment

Other tools test ground fault circuit interrupter devices and load levels. These tools find problems that visual checks miss. Proper tools improve accuracy. They also reduce uncertainty in results.

Cost of a Home Electrical Inspection

What Is the Average Cost for a Home Electrical Inspection

Most home electrical inspections in New Jersey cost $150 to $300 for a standard diagnostic visit. Extended inspections or complex systems are often billed at about $200 per hour. Emergency or after-hours calls usually start at $350 per hour.

Factors That Affect Pricing

Local rules and inspection types also affect price. A safety check costs less than a full code compliance review. Scheduling an electrical inspection with a defined goal helps control cost. Transparency supports planning.

What Happens After the Inspection

Inspection Reports and Findings

After the inspection, homeowners receive a written report. The report lists fire hazards, code violations, and safety concerns. Clear records support decisions and planning. The report also guides follow-up electrical work.

Required Fixes and Next Steps

Ignoring inspection findings can create bigger problems. Code violations can delay sales or affect insurance. Small issues, such as loose connections, can escalate into fire risks. Clear priorities help homeowners plan repairs.

As a Bergen County Generac Certified Installer, Grounded Electric also understands how inspections relate to generator readiness when needed. Some issues need fast action, while others can wait. Preventing electrical problems often involves planned steps.

If you need clarity on your system or next steps, you can schedule a consultation with Grounded Electric to review your inspection findings and options.